Nā kumu hoʻoheheʻe SMT

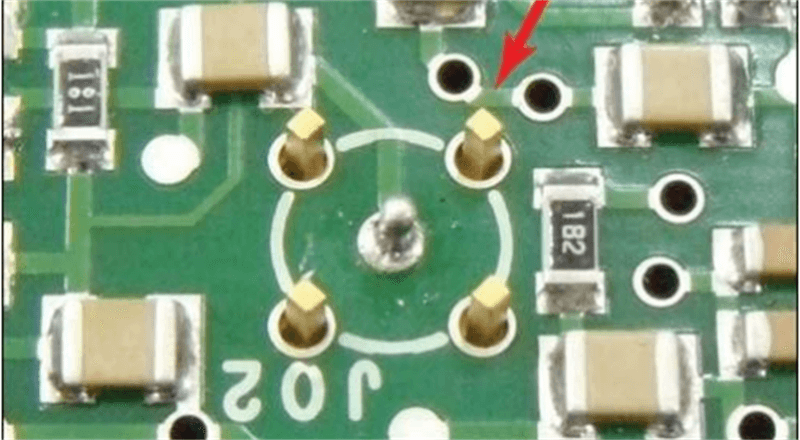

1. ʻO nā hemahema hoʻolālā PCB pad

I ke kaʻina hana hoʻolālā o kekahi PCB, no ka mea he liʻiliʻi ka wahi, hiki ke pāʻani wale ʻia ka lua ma ka pā, akā he fluidity ka solder paste, hiki ke komo i loko o ka lua, ka hopena i ka nele o ka solder paste i ka reflow welding, no laila inā ʻaʻole lawa ka pine e ʻai ai i ka tin, e alakaʻi ia i ka wili uila.

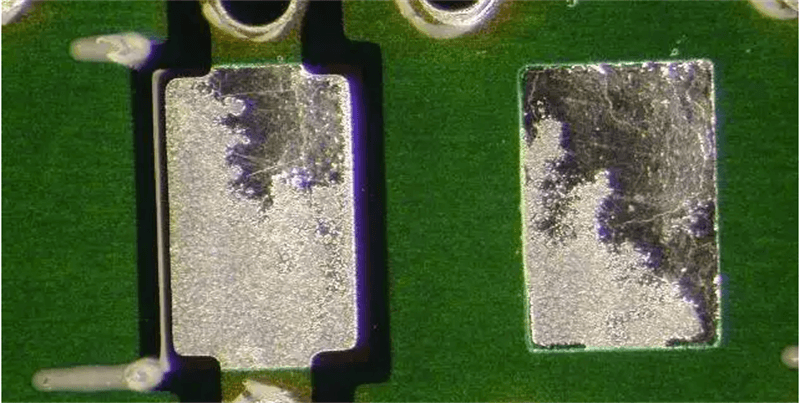

2.Pad ili oxidation

Ma hope o ka hoʻomaʻamaʻa hou ʻana i ka pad oxidized, ʻo ka reflow welding e alakaʻi i ka wiliwili virtual, no laila ke hoʻoheheʻe ʻia ka pad, pono e maloʻo mua. Inā koʻikoʻi ka oxidation, pono e haʻalele.

ʻAʻole lawa ka mahana 3.Reflow a i ʻole ke kiʻekiʻe wela o ka manawa

Ma hope o ka pau ʻana o ka pā, ʻaʻole lawa ka mahana i ka wā e hele ai i loko o ka reflow preheating zone a me ka ʻāpana wela mau, ka hopena i kekahi o ka wela wela piʻi piʻi ʻaʻole i loaʻa ma hope o ke komo ʻana i ke kiʻekiʻe kiʻekiʻe reflow zone, ka hopena i ka lawa ʻole o ka ʻai ʻana o ka ʻāpana ʻāpana, ka hopena i ka welding virtual.

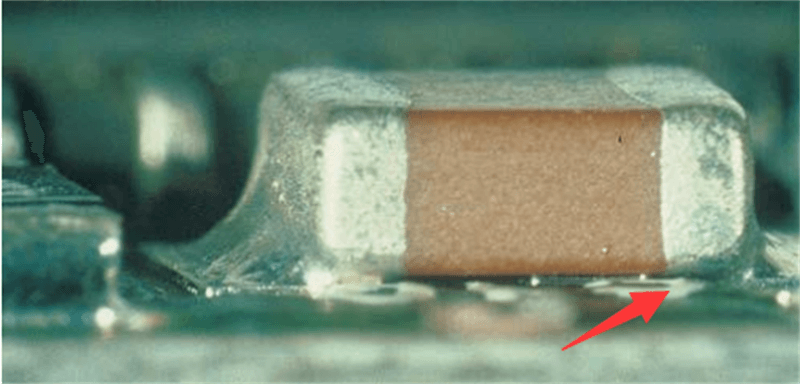

4. He emi iho ka pa'i pa'i pa'i

I ka wa a ka solder paste i palaki ia, ma muli paha o ka uuku wehe i loko o ke kila mesh a excessive kaomi o ka paʻi scraper, ka hopena i emi solder paʻi paʻi a me ka wikiwiki volatilization o ka solder paʻi no ka reflow kuʻihao, hopena i ka virtual kuʻihao.

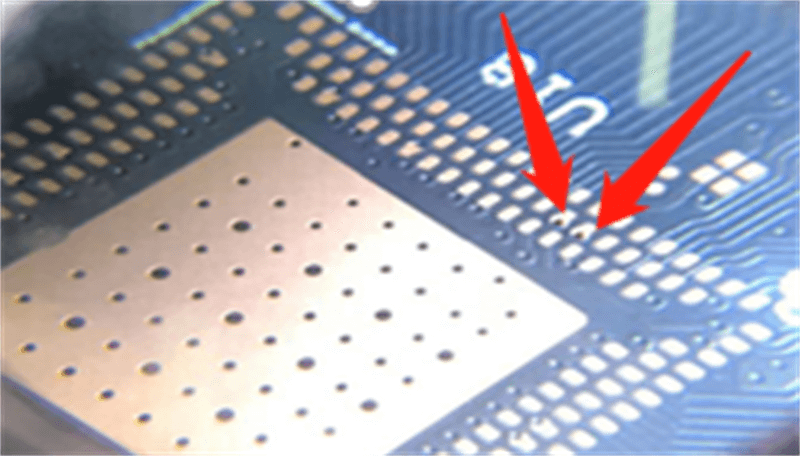

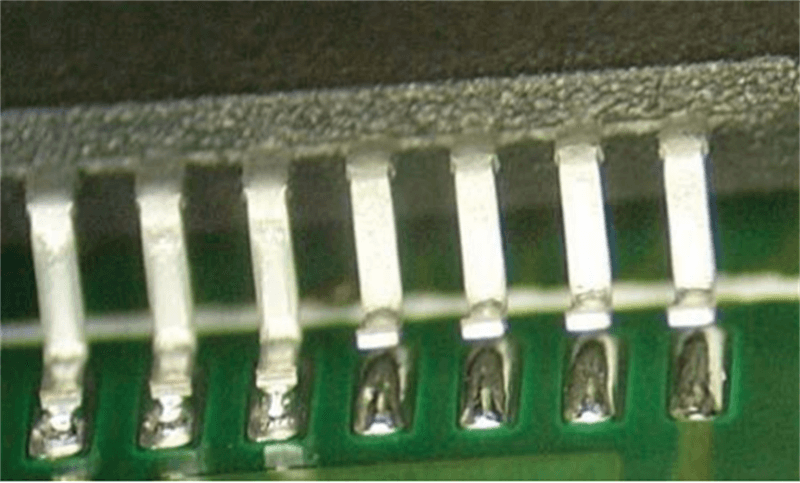

5. High-pin mea hana

Ke SMT ka mea kiʻekiʻe-pin, hiki paha i kekahi kumu, ua deformed ka ʻāpana, ua kūlou ka papa PCB, a i ʻole ka lawa ʻole o ke kaomi ʻino o ka mīkini hoʻokomo, e hopena i ka hoʻoheheʻe wela ʻokoʻa o ka solder, ka hopena i ka wiliwili virtual.

DIP mau kumu wiliwili virtual

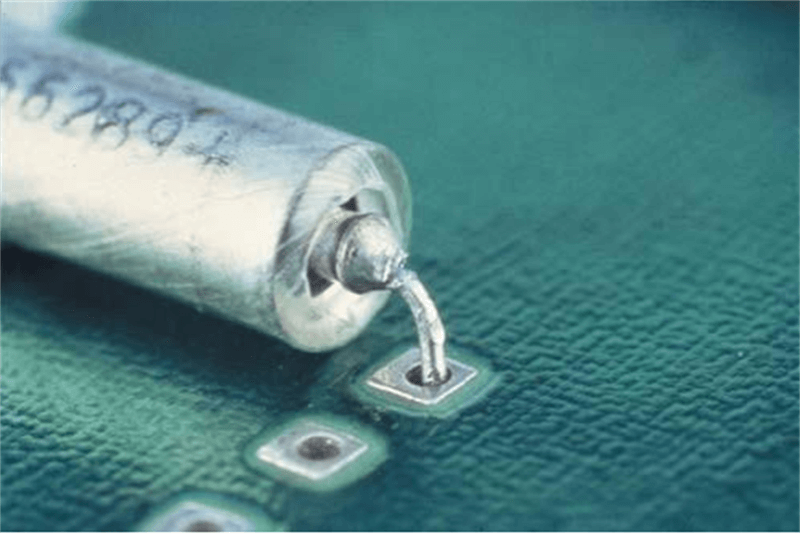

1.PCB plug-in hole design defects

ʻO ka PCB plug-in hole, ʻo ka hoʻomanawanui ma waena o ± 0.075mm, ʻoi aku ka nui o ka puka pahu PCB ma mua o ka pine o ka mea kino, e wehe ʻia ka hāmeʻa, e hopena i ka lawa ʻole o ka tin, ka hoʻoheheʻe virtual a i ʻole ka hoʻopili ʻana i ka ea a me nā pilikia ʻē aʻe.

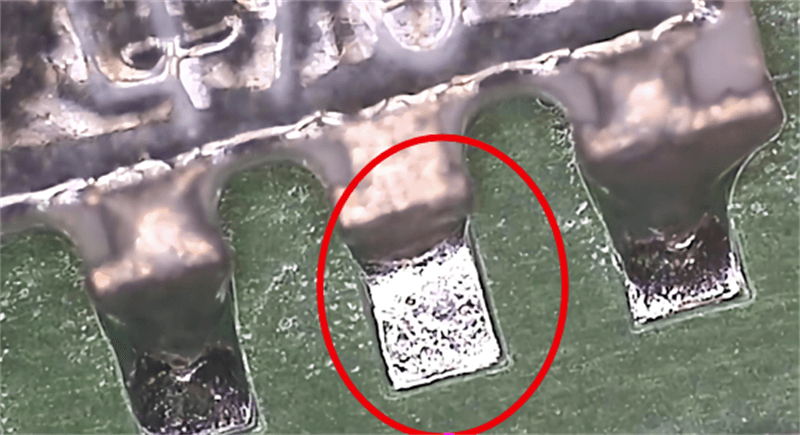

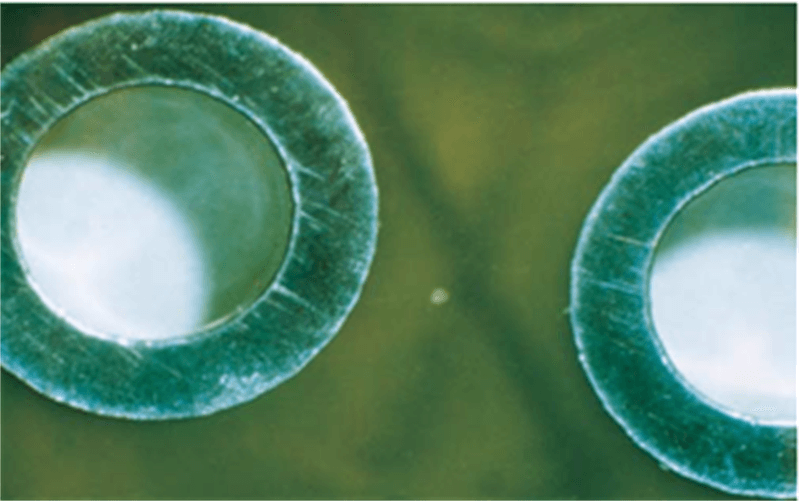

2.Pad a me ka hole oxidation

He haumia, oxidized, a haumia paha nā puka pā PCB me nā waiwai ʻaihue, ka momona, nā ʻōpala hou, a me nā mea ʻē aʻe, e alakaʻi ai i ka weldability maikaʻi ʻole a i ʻole ka weldability, e hopena ai i ka wiliwili virtual a me ka welding ea.

3. ʻO ka papa PCB a me nā mea maikaʻi

ʻAʻole kūpono nā papa PCB i kūʻai ʻia, nā ʻāpana a me nā mea solderability ʻē aʻe, ʻaʻole i hoʻokō ʻia ka hoʻāʻo ʻae ʻana, a aia nā pilikia maikaʻi e like me ka wili uila i ka wā o ka hui.

4. Ua pau ka papa PCB a me ka mea hana

Ua kūʻai ʻia nā papa PCB a me nā ʻāpana, ma muli o ka lōʻihi o ka manawa inventory, i hoʻopilikia ʻia e ka hale waihona, e like me ka mahana, ka haʻahaʻa a i ʻole nā kinoea corrosive, e hopena ai i nā hanana welding e like me ka welding virtual.

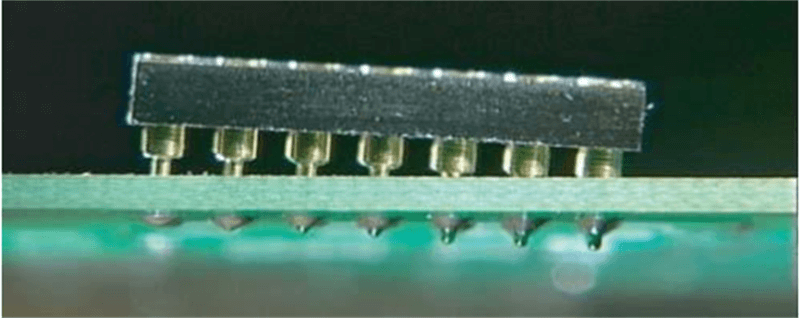

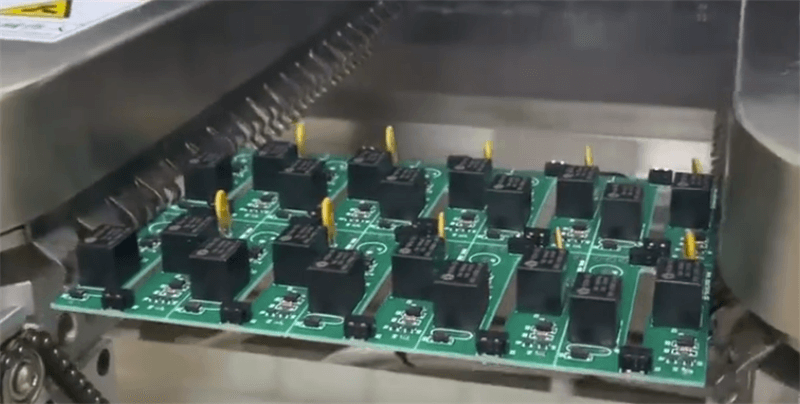

5. Wave soldering lako kumu

ʻO ke kiʻekiʻe o ka wela o ka umu welding nalu e alakaʻi i ka oxidation wikiwiki o ka mea solder a me ka ʻili o ka mea kumu, e hoʻemi ana i ka hoʻopili ʻana o ka ʻili i ka mea solder wai. Eia kekahi, hoʻopau ka wela kiʻekiʻe i ka ʻili o ka mea kumu, e hoʻemi ana i ka hana capillary a me ka diffusivity maikaʻi ʻole, ka hopena i ka wiliwili virtual.

Ka manawa hoʻouna: Jul-11-2023