1 Hoolauna

I ka hui papa kaapuni, paʻi ʻia ka paʻi solder ma ka papa solder pad ma mua, a laila hoʻopili ʻia nā mea uila like ʻole. ʻO ka hope loa, ma hope o ka hoʻoheheʻe ʻana o ka umu, ua hoʻoheheʻe ʻia nā pahu pahu i loko o ka paʻi solder a hoʻoheheʻe ʻia nā ʻano mea uila like ʻole a me ka pā solder o ka papa kaapuni e ʻike i ka hui ʻana o nā submodules uila. surfacemounttechnology (sMT) ua increasingly hoʻohana 'ia i kiʻekiʻe-density paʻi huahana, e like me ka nenoaiu pae puʻupuʻu (siP), ballgridarray (BGA) mea, a me ka mana pahu Chip, huinaha palahalaha pin-emi pūʻolo (quad aatNo-lead, i kapaia QFN).

Ma muli o nā hiʻohiʻona o ka solder paste welding kaʻina hana a me nā mea waiwai, ma hope o ka reflow weld o kēia mau mea nui solder surface, e loaʻa nā lua i ka solder welding area, e hoʻopilikia i nā waiwai uila, nā mea wela a me nā waiwai mechanical o ka huahana Performance, a hiki i ka hopena o ka huahana, no laila, e hoʻomaikaʻi i ka solder paste reflow welding cavity i lilo i kaʻina hana a me ka pilikia ʻenehana pono e hoʻoponopono ʻia, a ua noiʻi kekahi poʻe noiʻi i nā kumu o ka BGA. hāʻawi ʻia nā hoʻonā hoʻomaikaʻi, kaʻina hana hoʻoheheʻe reflow kuʻuna maʻamau o ka QFN ʻoi aku ka nui ma mua o 10mm2 a i ʻole ka wahi kuʻihao ʻoi aku ma mua o 6 mm2 ʻaʻole nele.

E hoʻohana i ka wiliwili Preformsolder a me ka hoʻoheheʻe ʻana i ka umu ahi reflux e hoʻomaikaʻi i ka lua weld. Pono ka solder prefabricated i nā lako kūikawā e kuhikuhi i ka flux. No ka laʻana, hoʻoneʻe ʻia ka chip a hili ʻia ma hope o ke kau pololei ʻana o ka chip ma luna o ka solder prefabricated. Inā hoʻihoʻi hou ka puʻu puʻu flux a laila kuhikuhi, hoʻonui ʻia ke kaʻina hana e ʻelua reflow, a ʻoi aku ka kiʻekiʻe o ke kumukūʻai o ka solder prefabricated a me nā mea flux ma mua o ka paʻi solder.

ʻOi aku ke kumukūʻai o ka mīkini hoʻoheheʻe vacuum, ʻoi aku ka haʻahaʻa o ka nui o ke keʻena kūʻokoʻa kūʻokoʻa, ʻaʻole kiʻekiʻe ke kumukūʻai, a he koʻikoʻi ka pilikia splashing tin, he mea nui ia i ka hoʻohana ʻana i nā huahana kiʻekiʻe a me nā mea liʻiliʻi. I loko o kēia pepa, e pili ana i ke kaʻina hana hoʻoheheʻe reflow kuʻuna maʻamau, ua hoʻomohala ʻia kahi kaʻina hana wili hou lua hou e hoʻomaikaʻi ai i ka lua kuʻi a hoʻonā i nā pilikia o ka hoʻopaʻa ʻana a me ka haki ʻana o ka sila i hoʻokumu ʻia e ka lua wili.

2 Solder paste paʻi reflow kuʻihao lua a me ka hana hana

2.1 Ka lua wiliwili

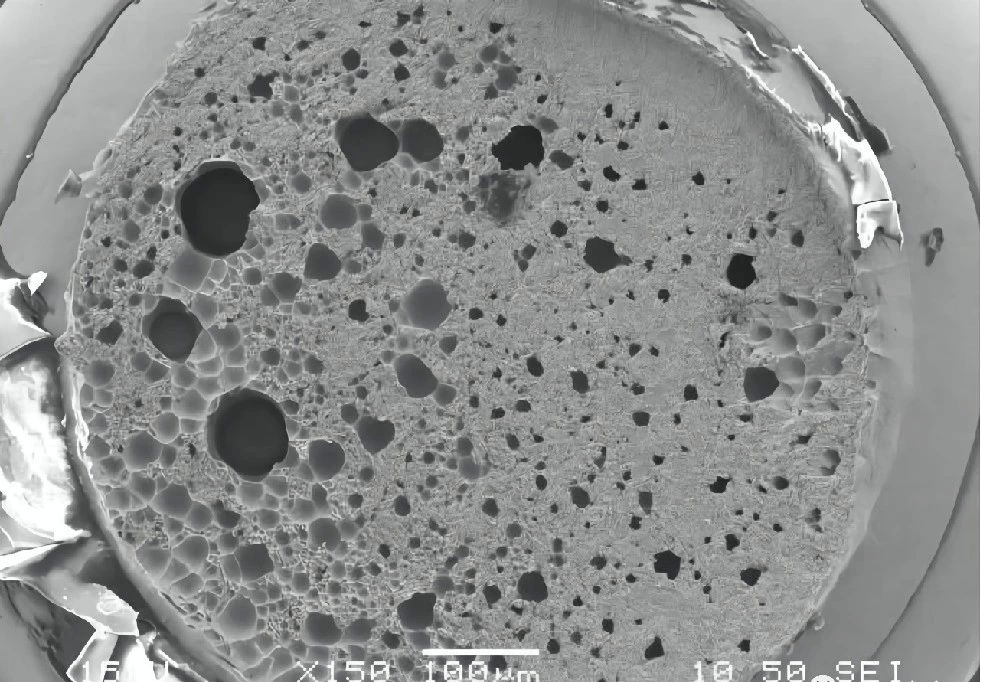

Ma hope o ka reflow welding, ua hoʻāʻo ʻia ka huahana ma lalo o ka x-ray. Ua ʻike ʻia nā puka i loko o ka ʻāpana hoʻoheheʻe me ke kala ʻoi aku ka māmā ma muli o ka lawa ʻole o ka solder i ka papa kuʻi, e like me ka hōʻike ʻana ma ka Figure 1

ʻIke X-ray o ka puka ʻōhū

2.2 Hoʻokumu ʻia o ka lua kuʻi

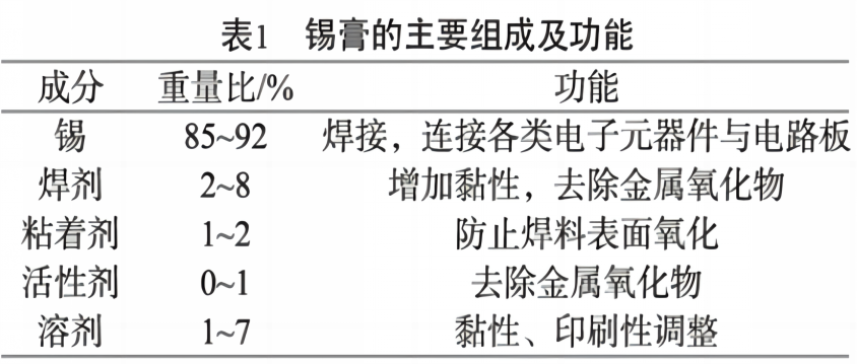

I ka lawe ʻana i ka paʻi solder sAC305 ma ke ʻano he laʻana, ua hōʻike ʻia ka haku mele a me ka hana nui ma ka Papa 1. Ua hoʻopaʻa ʻia ka flux a me nā pahu tin i ke ʻano paʻi. ʻO ka lakio paona o ka solder tin a flux ma kahi o 9: 1, a ʻo ka ratio o ka leo ma kahi o 1: 1.

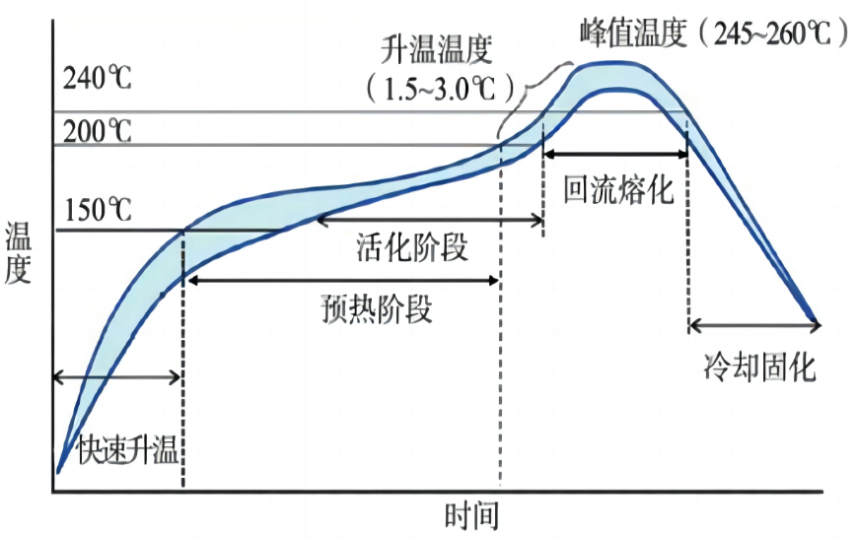

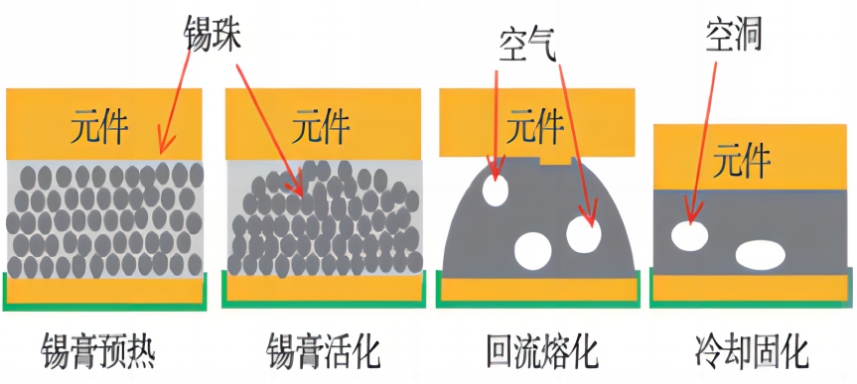

Ma hope o ka paʻi ʻia ʻana o ka paʻi solder a kau ʻia me nā ʻāpana uila like ʻole, e hana ʻia ka paʻi solder i ʻehā mau ʻanuʻu o ka preheating, activation, reflux a me ka hoʻomaha ʻana i ka wā e hele ai i ka umu reflux. ʻOkoʻa nō hoʻi ke kūlana o ka paʻi solder me nā mahana like ʻole i nā pae like ʻole, e like me ka hōʻike ʻana ma ke Kiʻi 2.

Hōʻike hōʻike no kēlā me kēia wahi o ka reflow soldering

I ka wā preheating a me ka ho'āla ʻana, e hoʻoheheʻe ʻia nā ʻāpana volatile i ka flux o ka solder paste i ke kinoea i ka wā i wela ai. I ka manawa like, e hana ʻia nā kinoea i ka wā e wehe ʻia ai ka oxide ma ka ʻili o ka papa kuʻi. ʻO kekahi o kēia mau kinoea e hoʻoheheʻe a haʻalele i ka paʻi solder, a e hoʻopili paʻa ʻia nā pahu solder ma muli o ka volatilization o ka flux. I ka pae reflux, e hoʻoheheʻe koke ʻia ke koena o ka paʻi solder, e hoʻoheheʻe nā pahu tin, kahi liʻiliʻi o ka flux volatile gas a ʻo ka hapa nui o ka ea ma waena o nā pahu tin ʻaʻole e hoʻopuehu ʻia i ka manawa, a ʻo ke koena i loko o ka pahu hoʻoheheʻe ʻia a ma lalo o ke ʻano o ka pahu hoʻoheheʻe ʻia he hamburger sandwich structure a hopu ʻia e ka paʻa wai paʻa a paʻa i ka papa uila. e pakele wale ma ka hooluolu iluna He pōkole loa ka manawa hehee o luna. I ka wā e maʻalili ai ka ipu i hoʻoheheʻe ʻia a lilo i kī paʻa, ʻike ʻia nā pores i ka papa wili a hana ʻia nā lua solder, e like me ka hōʻike ʻana ma ke Kiʻi 3.

ʻO ke kiʻikuhi schematic o ka ʻole i hana ʻia e ka solder paste reflow welding

ʻO ke kumu o ka hoʻoheheʻe ʻana ʻo ia ʻaʻole i hoʻokuʻu ʻia ka ea a i ʻole ke kinoea volatile i ʻōwili ʻia i loko o ka solder paste ma hope o ka hoʻoheheʻe ʻana. ʻO nā mea e hoʻoulu ai, ʻo ia ka mea paʻi paʻi solder, ke ʻano paʻi paʻi solder, ka nui o ka paʻi paʻi solder, ka mahana reflux, ka manawa reflux, ka nui wili, ka hale a pēlā aku.

3. Ka hōʻoia ʻana i nā kumu hoʻohālikelike o ka paʻi paʻi ʻana i nā lua wili reflow

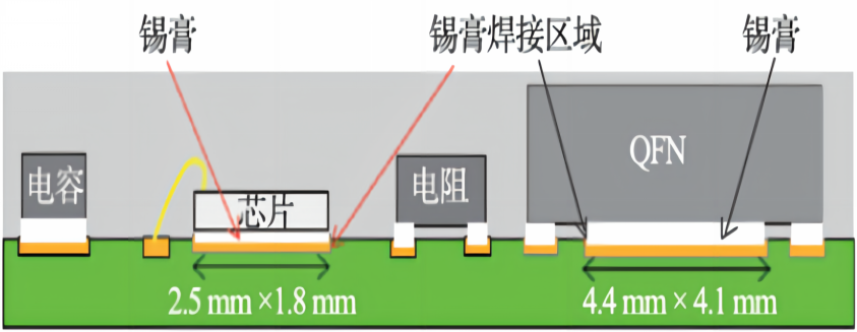

Ua hoʻohana ʻia nā hoʻāʻo QFN a me nā pahu pahu pahu e hōʻoia i nā kumu nui o ka reflow welding voids, a no ka ʻimi ʻana i nā ala e hoʻomaikaʻi ai i ka reflow welding voids i paʻi ʻia e ka solder paste. Hōʻike ʻia ʻo QFN a me ka pahu kuʻi pahu pahu reflow kuʻihao huahana ma ke kiʻi 4, ʻo ka nui o ka ili kuʻi QFN he 4.4mmx4.1mm, ʻo ka ili kuʻi ʻana he papa tinned (100% tinned maʻemaʻe); ʻO 3.0mmx2.3mm ka nui o ke kuʻi ʻana o ka ʻōpala, ʻo ka papa kuʻi ʻana he nickel-vanadium bimetallic layer, a ʻo ka papa honua he vanadium. ʻO ke kuʻihao pad o ka substrate he electroless nickel-palladium gula-luu, a me ka mānoanoa he 0.4μm / 0.06μm / 0.04μm. Hoʻohana ʻia ʻo SAC305 solder paste, ʻo ka mea paʻi paʻi solder ʻo DEK Horizon APix, ʻo ka mea hoʻoheheʻe reflux ʻo BTUPyramax150N, a ʻo ka mea hana x-ray ʻo DAGExD7500VR.

QFN a me nā kiʻi hoʻoheheʻe puʻupuʻu ʻole

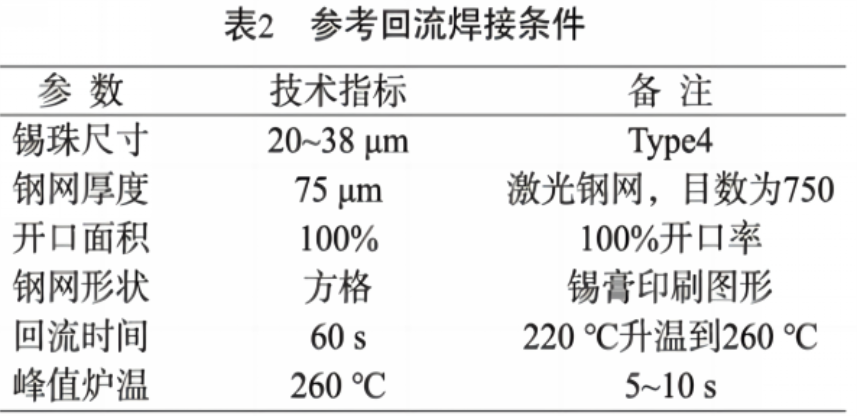

No ka maʻalahi o ka hoʻohālikelike ʻana i nā hopena hoʻāʻo, ua hana ʻia ka reflow welding ma lalo o nā kūlana ma ka Papa 2.

Pakaukau kūlana kuʻi hou

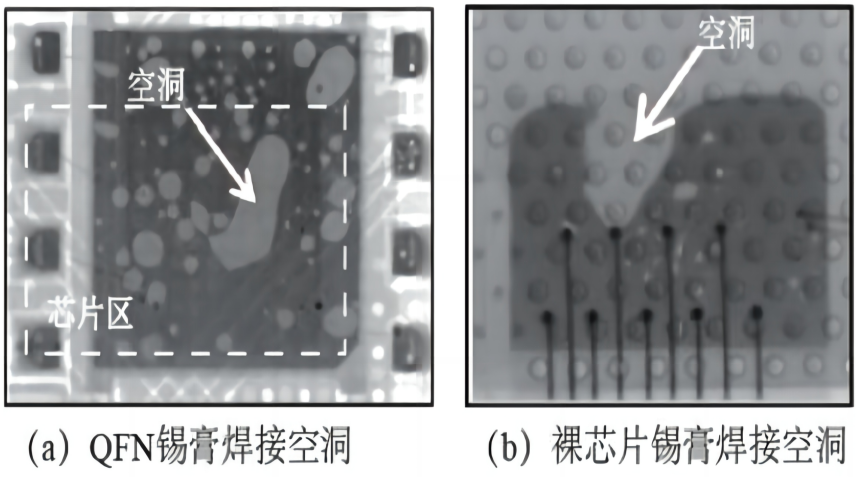

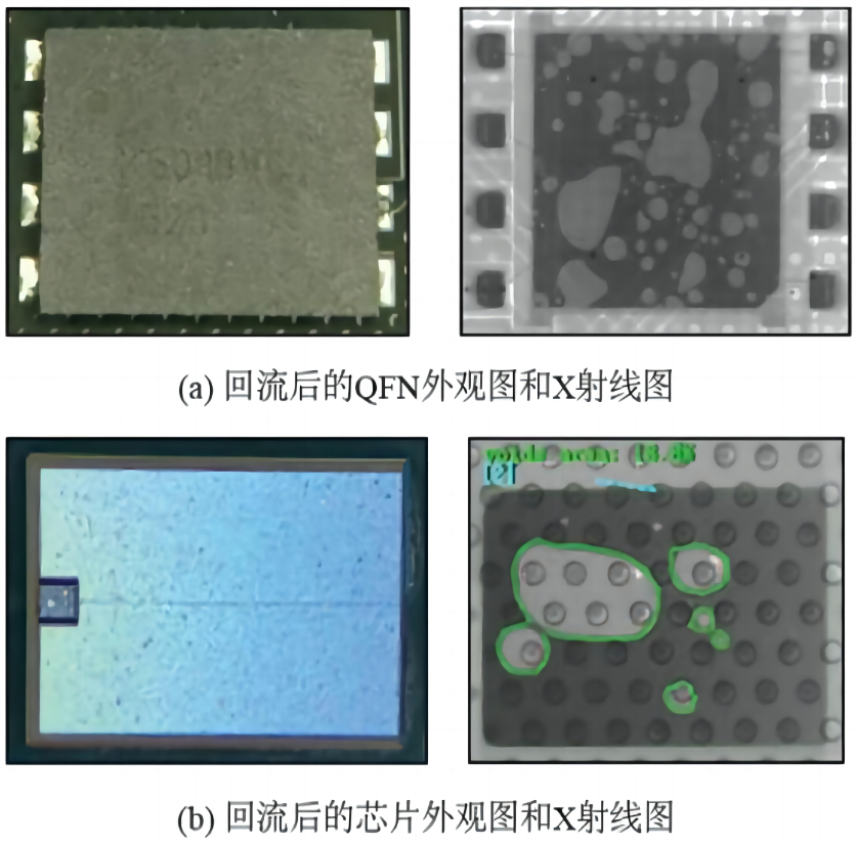

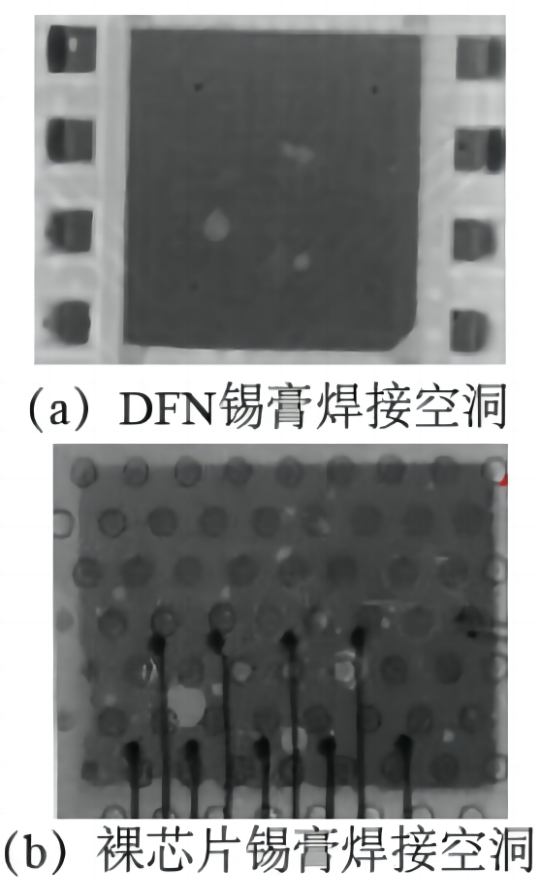

Ma hope o ka pau ʻana o ka hoʻopili ʻana o ka ʻili a me ka hoʻokuʻi hou ʻana, ua ʻike ʻia ka papa kuʻihao e ka X-ray, a ua ʻike ʻia aia nā lua nui ma ka papa kuʻi ma lalo o QFN a me ka pahu pahu, e like me ka hōʻike ʻana ma ke Kiʻi 5.

QFN a me Chip Hologram (X-ray)

Ma muli o ka nui o ka tin bead, ka mānoanoa o ke kila, ka nui o ka wehe ʻana, ke ʻano mesh mesh, ka manawa reflux a me ka wela o ka umu wela e hoʻopili i nā lua hoʻoheheʻe reflow, he nui nā kumu hoʻohālikelike, e hōʻoia pololei ʻia e ka DOE test, a ʻoi aku ka nui o nā hui hoʻokolohua. Pono e nānā a hoʻoholo i nā kumu hoʻohālikelike nui ma o ka hoʻohālikelike correlation hoʻohālikelike, a laila hoʻomaikaʻi hou i nā kumu hoʻoikaika nui ma o DOE.

3.1 Nā ana o nā lua solder a me nā ʻeke pī

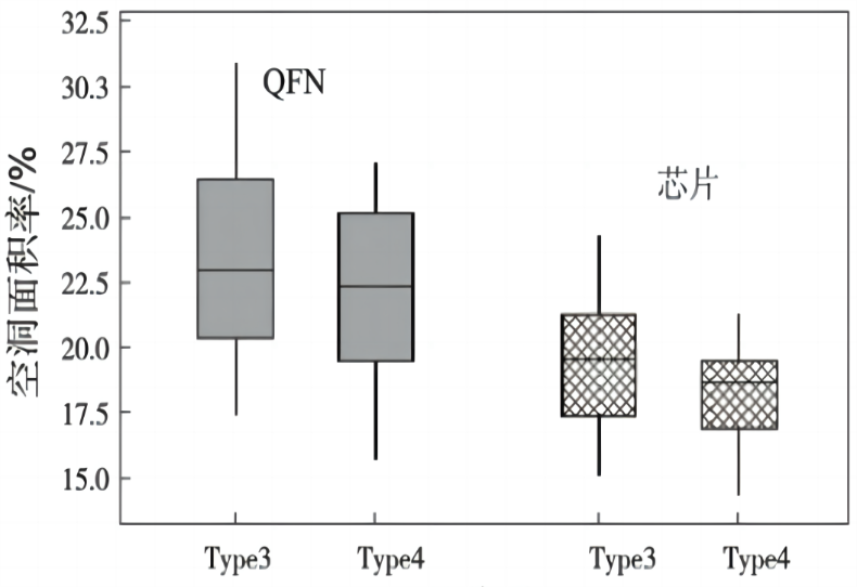

Me ka type3 (ka nui bead 25-45 μm) SAC305 solder paste test, ʻaʻole i loli nā kūlana ʻē aʻe. Ma hope o ka reflow, ana ʻia nā puka o ka papa solder a hoʻohālikelike ʻia me ka paʻi solder type4. Ua ʻike ʻia ʻaʻole ʻokoʻa loa nā puka o ka papa solder ma waena o nā ʻano ʻelua o ka paʻi solder, e hōʻike ana ʻaʻole i maopopo ka mana o ka paʻi solder me ka nui o ka bead ʻokoʻa i nā lua o ka papa solder, ʻaʻole ia he mea hoʻoikaika, e like me ka hōʻike ʻana ma FIG. 6 E like me ka hoike ana.

Ka hoohalike ana o na puka pauda metala me na ano nui okoa

3.2 Mānoanoa o ka lua kuʻihao a pai ʻia mesh kila

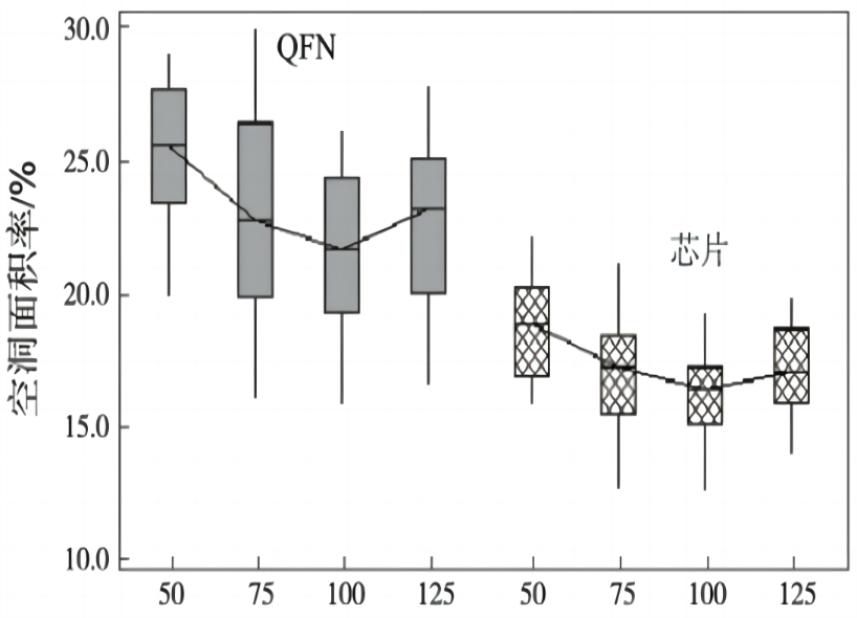

Ma hope o ka reflow, ua ana ʻia ka ʻāpana lua o ka papa welded me ka mesh kila i paʻi ʻia me ka mānoanoa o 50 μm, 100 μm a me 125 μm, a ʻaʻole i hoʻololi ʻia nā kūlana ʻē aʻe. Uaʻikeʻia ua hoʻohālikelikeʻia ka hopena o ka mānoanoa likeʻole o ka mesh kila (solder paste) ma QFN me ka mea o ka mīkini kila i paʻiʻia me ka mānoanoa o 75 μm I ka piʻiʻana o ka mānoanoa o ke kila mesh, e emi mālie ka'āpana o ka lua. Ma hope o ka hiki ʻana i kahi mānoanoa (100μm), e huli ka ʻāpana o ka lua a hoʻomaka e hoʻonui me ka hoʻonui ʻana i ka mānoanoa o ka mesh kila, e like me ka hōʻike ʻana ma ke Kiʻi 7.

Hōʻike kēia i ka wā e hoʻonui ʻia ai ka nui o ka paʻi solder, ua uhi ʻia ka pahu wai me ka reflux e ka chip, a ʻo ka puka o ke koena ea e pakele ai he haiki wale nō ma nā ʻaoʻao ʻehā. Ke hoʻololi ʻia ka nui o ka paʻi solder, hoʻonui ʻia ka puka o ke koena o ka ea e pakele ai, a ʻo ka huʻi koke ʻana o ka ea i wahī ʻia i loko o ka pahu wai a i ʻole ke kinoea hoʻoheheʻe e pakele ai i ka pahu wai e hoʻoheheʻe ʻia ka pahu wai a puni ka QFN a me ka chip.

Ua ʻike ʻia ka hoʻāʻo ʻana me ka piʻi ʻana o ka mānoanoa o ka mesh kila, e hoʻonui ʻia ka huʻihuʻi ma muli o ka mahuka ʻana o ka ea a i ʻole ke kinoea hoʻoheheʻe ʻia, a e piʻi aʻe hoʻi ka nui o ke kīpē a puni QFN a me ka chip.

Hoʻohālikelike o nā puka i loko o ke kila mesh o ka mānoanoa like ʻole

3.3 Area lākiō o ka welding lua a me ke kila mesh wehe

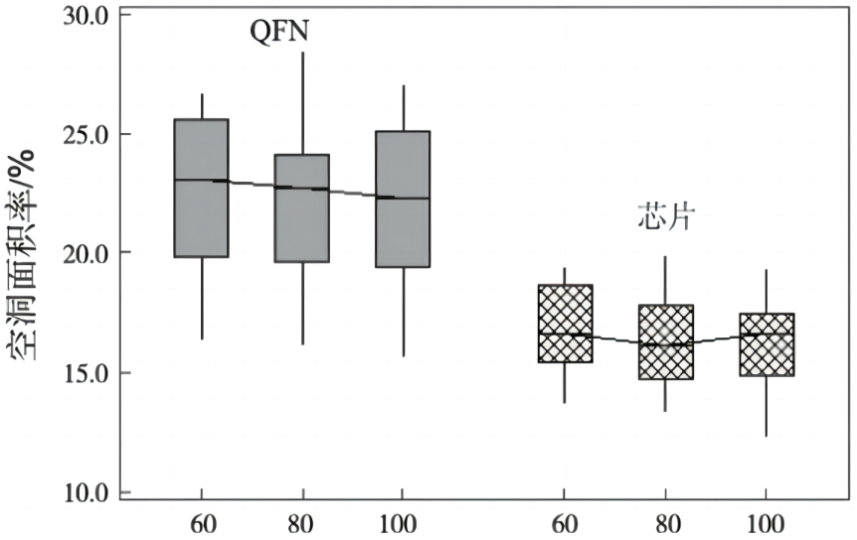

Ua ho'āʻoʻia ka mīkini kila i paʻiʻia me ka weheʻana o 100%, 90% a me 80%, aʻaʻole i loli nā kūlana'ē aʻe. Ma hope o ka reflow, ua ana ʻia ka ʻāpana lua o ka papa welded a hoʻohālikelike ʻia me ka mesh kila i paʻi ʻia me ka 100% wehe. Ua ʻike ʻia ʻaʻohe ʻokoʻa nui o ka lua o ka papa welded ma lalo o nā kūlana o ka wehe ʻana o 100% a me 90% 80%, e like me ka hōʻike ʻana ma ka Figure 8.

Hoʻohālikelike lua o nā wahi wehe ʻokoʻa o nā mesh kila like ʻole

3.4 Welded lua a paiʻia kila mesh kino

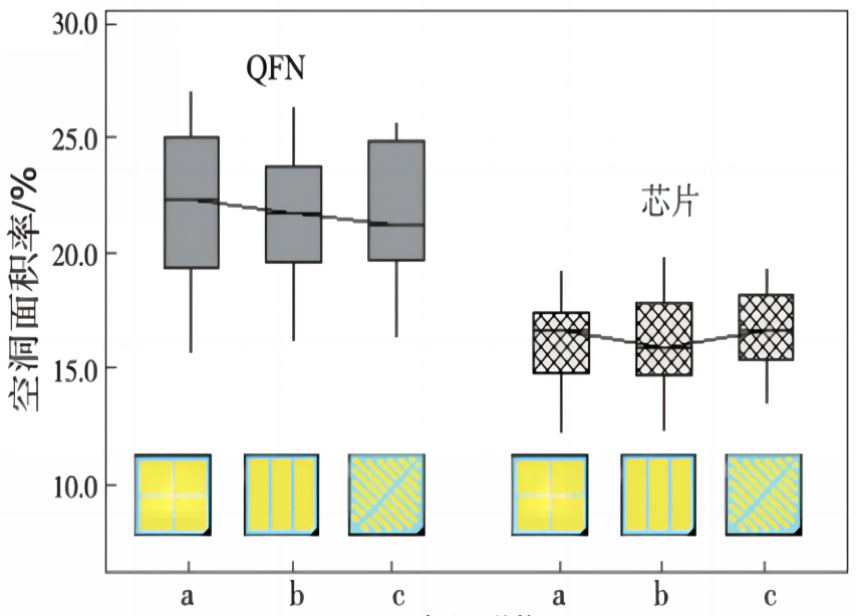

Me ka hoʻāʻo ʻana i ke ʻano paʻi o ka paʻi solder o ka strip b a me ka pahu kuhi c, ʻaʻole i loli nā kūlana ʻē aʻe. Ma hope o ka reflow, ana ʻia ka ʻāpana lua o ka papa kuʻihao a hoʻohālikelike ʻia me ke ʻano paʻi o ka grid a. ʻIke ʻia ʻaʻohe ʻokoʻa koʻikoʻi o ka lua o ka papa kuʻihao ma lalo o nā kūlana o ka grid, strip a inclined grid, e like me ka mea i hōʻike ʻia ma ke Kiʻi 9.

Hoʻohālikelike o nā puka ma nā ʻano wehe ʻokoʻa o ke kila mesh

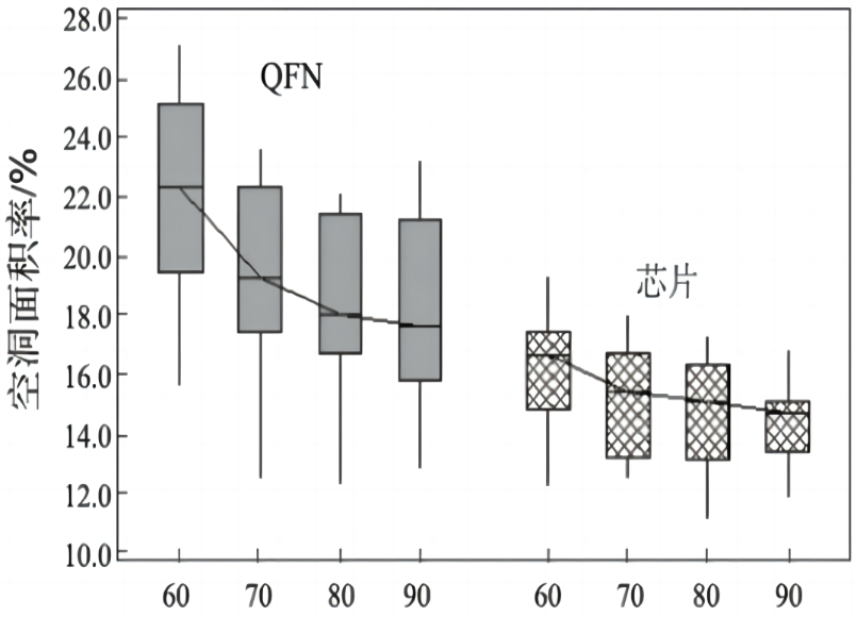

3.5 Welding lua a me ka reflux manawa

Ma hope o ka manawa reflux lōʻihi (70 s, 80 s, 90 s) ho'āʻo, mau kūlana ʻē aʻe ʻaʻole i hoʻololi ʻia, ua ana ʻia ka lua i ka papa kuʻihao ma hope o ka reflux, a hoʻohālikelike ʻia me ka manawa reflux o 60 s, ua ʻike ʻia me ka piʻi ʻana o ka manawa reflux, ua emi ka wahi o ka lua kuʻi, akā ʻo ka hōʻemi ʻana o ka amplitude i hōʻike ʻia i ka manawa 1. ʻO ka hihia o ka manawa reflux lawa ʻole, ʻo ka hoʻonui ʻana i ka manawa reflux e kūpono i ka piha piha ʻana o ka ea i kāwili ʻia i loko o ka pahu wai hoʻoheheʻe, akā ma hope o ka piʻi ʻana o ka manawa reflux i kekahi manawa, paʻakikī ke kahe hou ʻana o ka ea i ʻōwili ʻia i loko o ka ipu wai. ʻO ka manawa reflux kekahi o nā mea e pili ana i ka lua welding.

Hoʻohālikelike ʻole i nā lōʻihi manawa reflux like ʻole

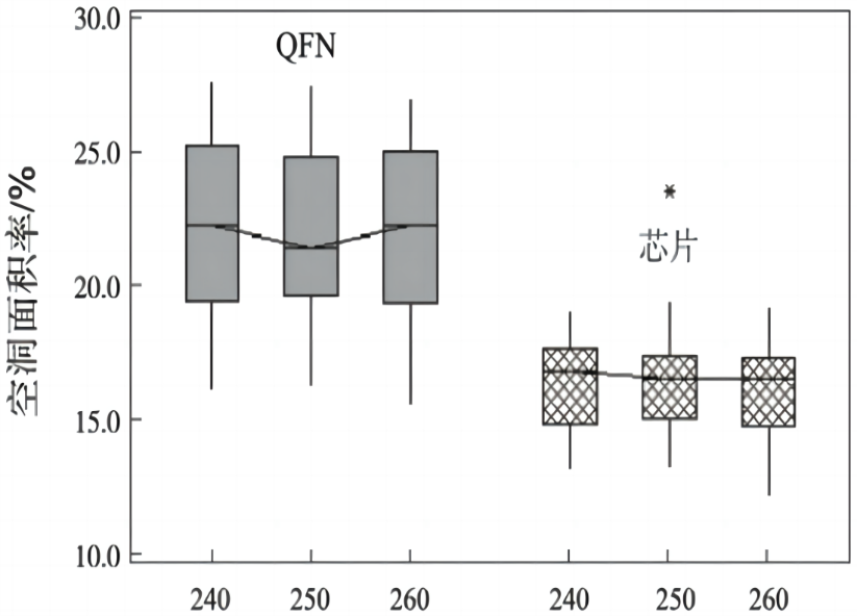

3.6 Welding lua a me ka wela wela wela

Me ka 240 ℃ a me 250 ℃ peak furnace temperature test a me nā kūlana ʻē aʻe ʻaʻole i hoʻololi ʻia, ua ana ʻia ka ʻāpana lua o ka papa welded ma hope o ka reflow, a hoʻohālikelike ʻia me 260 ℃ peak umu wela, ua ʻike ʻia ma lalo o nā kūlana wela o ka umu wela, ʻo ka lua o ka welded layer o QFN a me ka chip i hōʻike ʻole ʻia. ʻAʻohe hopena o ka wela o ka umu ahi i ka QFN a me ka lua i ka papa kuʻihao o ka chip, ʻaʻole ia he mea hoʻohālikelike.

ʻAʻohe hoʻohālikelike o nā wela kiʻekiʻe like ʻole

Hōʻike nā hōʻike ma luna nei ʻo nā mea koʻikoʻi e pili ana i ka lua weld layer o QFN a me ka chip he manawa reflux a me ka mānoanoa mesh kila.

4 Hoʻonui ʻia ka hoʻomaikaʻi ʻana i ka hoʻoheheʻe ʻana i ka paʻi ʻana i ka paʻi ʻana

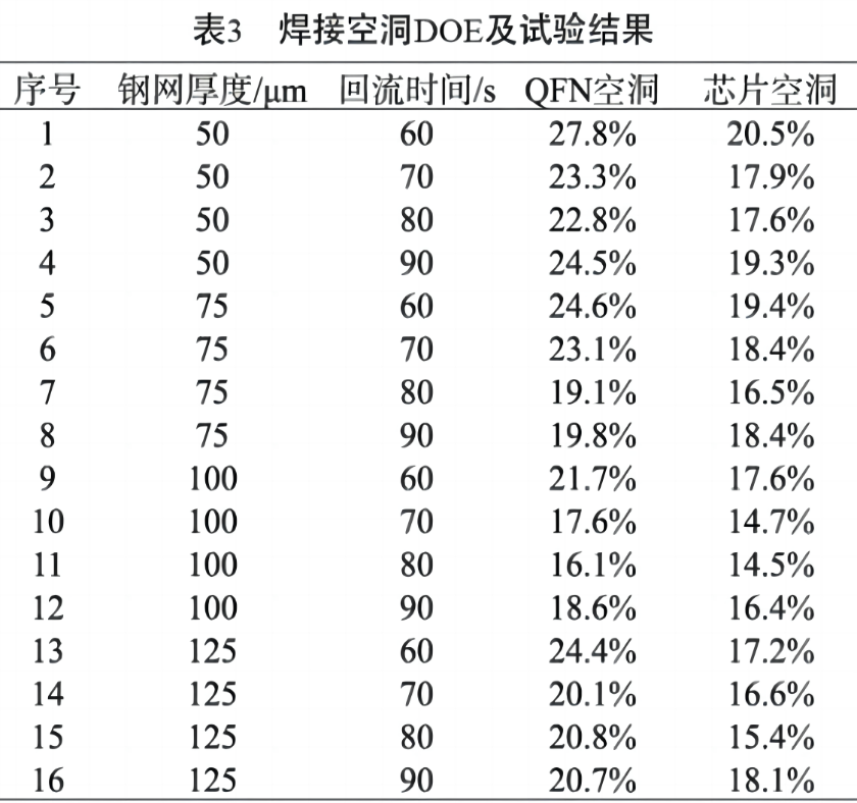

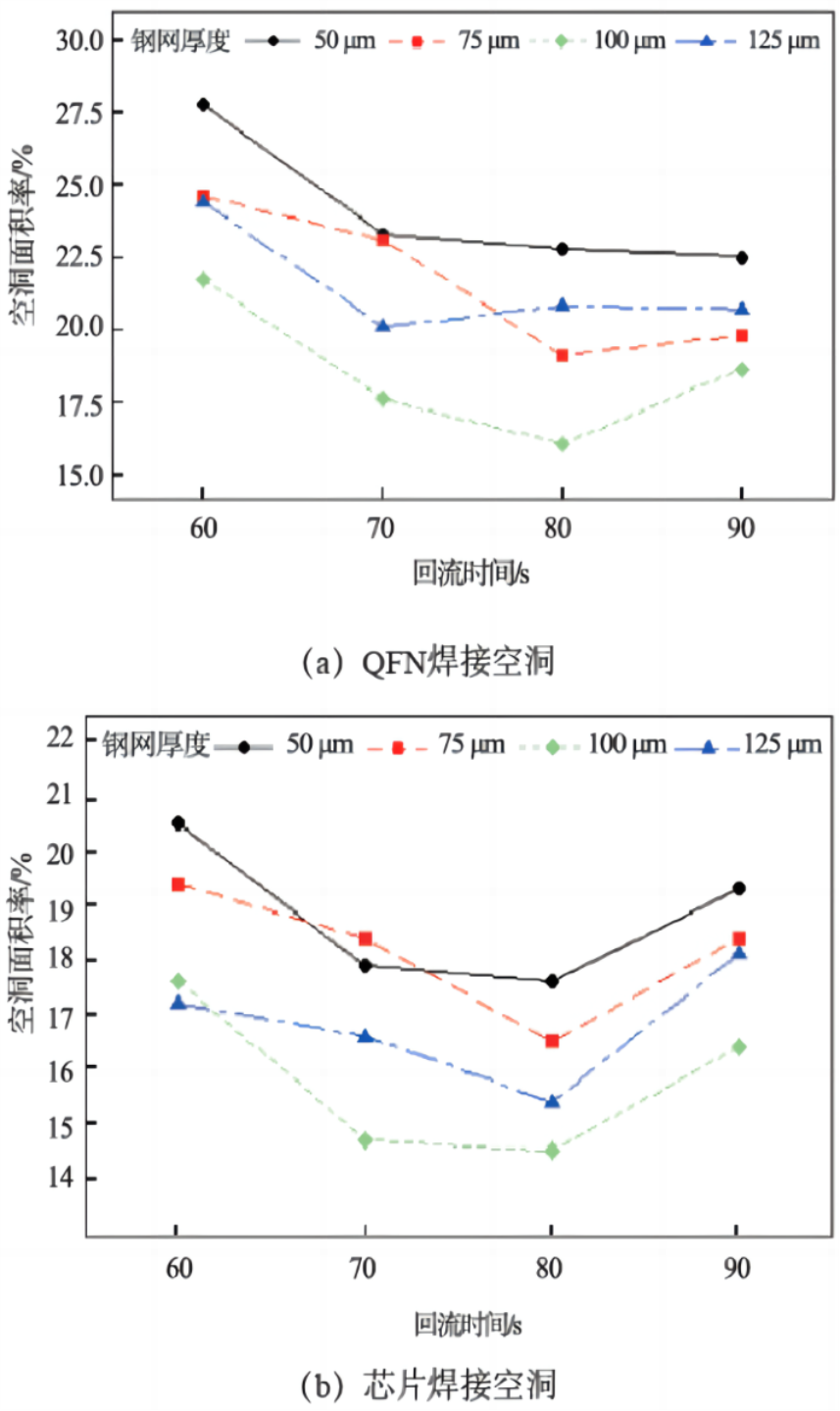

4.1 Ho'āʻo DOE e hoʻomaikaʻi i ka lua wili

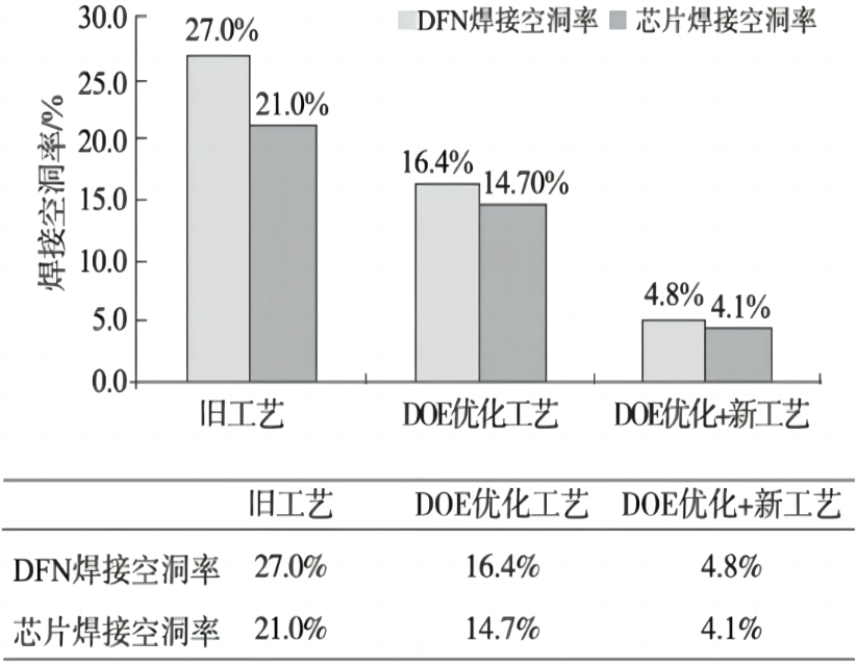

Ua hoʻomaikaʻi ʻia ka lua i ka papa kuʻihao o QFN a me ka chip ma ka loaʻa ʻana o ka waiwai maikaʻi loa o nā kumu hoʻoikaika nui (ka manawa reflux a me ka mānoanoa mesh kila). ʻO ka paʻi solder he SAC305 type4, ʻo ke ʻano mesh kila ke ʻano grid (100% wehe degere), ʻo ka wela o ka umu wela he 260 ℃, a ua like nā kūlana hoʻāʻo ʻē aʻe me nā mea hoʻāʻo. Hōʻike ʻia ka hoʻāʻo DOE a me nā hopena ma ka Papa 3. Ua hōʻike ʻia nā hopena o ka mānoanoa mesh kila a me ka manawa reflux ma QFN a me nā lua kuʻi chip i ka Figure 12. Ma o ka hoʻopili ʻana i nā mea hoʻohālikelike nui, ʻike ʻia ʻo ka hoʻohana ʻana i ka mānoanoa 100 μm kila a me 80 s reflux manawa hiki ke hoʻemi nui i ka lua kuʻi o QFN a me ka chip. Hoʻemi ʻia ka nui o ka welding cavity o QFN mai ka 27.8% kiʻekiʻe a hiki i 16.1%, a ua hoʻemi ʻia ka nui o ka welding cavity o chip mai ka 20.5% a hiki i 14.5%.

I ka hoʻāʻo ʻana, ua hana ʻia nā huahana 1000 ma lalo o nā kūlana maikaʻi loa (100 μm steel mesh mānoanoa, 80 s reflux time), a ua ana ʻia ka nui o ka lua o 100 QFN a me ka chip. He 16.4% ka awelika o ka nui o ka welding cavity o QFN, a he 14.7% ka awelika o ka weld cavity rate o ka chip a me ka chip.

4.2 Hoʻomaikaʻi ke kaʻina hana hou i ka lua wili

Ke hōʻike nei ke kūlana hana maoli a me ka hoʻāʻo ʻana i ka wā i emi ai ka ʻāpana o ka lua kuʻi ma lalo o ka chip ma mua o 10%, ʻaʻole e kū mai ka pilikia o ka puhaka i ka wā o ka hoʻopaʻa ʻana a me ka hoʻoheheʻe ʻana. ʻAʻole hiki i nā ʻāpana kaʻina hana i hoʻopaʻa ʻia e DOE i nā koi o ka nānā ʻana a me ka hoʻoponopono ʻana i nā lua o ka solder paste reflow welding maʻamau, a pono e hoʻemi hou ʻia ka nui o ka lua o ka puʻu.

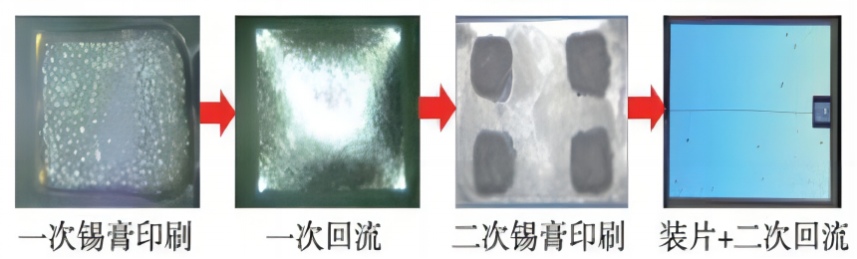

No ka mea, ʻo ka puʻupuʻu i uhi ʻia i ka solder e pale aku i ke kinoea i loko o ka solder mai ka pakele ʻana, e hoʻemi hou ʻia ka nui o ka puka ma lalo o ka chip ma ka hoʻopau ʻana a hōʻemi paha i ke kinoea i uhi ʻia. Hoʻohana ʻia kahi kaʻina hana hou o ka hoʻoheheʻe hou ʻana me ʻelua paʻi paʻi solder: hoʻokahi paʻi paʻi solder, hoʻokahi reflow ʻaʻole uhi i ka QFN a me ka pahu pahu pahu e hoʻokuʻu ana i ke kinoea i ka solder; Hōʻike ʻia ke kaʻina hana o ka paʻi paʻi solder lua, patch a me ka reflux lua ma ke Kiʻi 13.

Ke paʻi ʻia ka paʻi solder mānoanoa 75μm no ka manawa mua, ʻo ka hapa nui o ke kinoea i loko o ka solder me ka uhi ʻole chip i pakele mai ka ʻili, a ʻo ka mānoanoa ma hope o ka reflux ma kahi o 50μm. Ma hope o ka pau ʻana o ka reflux mua, paʻi ʻia nā ʻāpana liʻiliʻi ma ka ʻili o ka solder solidified cooled (i mea e hōʻemi ai i ka nui o ka solder paste, e hoʻemi i ka nui o ke kinoea spillover, hoʻemi a hoʻopau paha i ka solder spatter), a me ka solder paste me ka mānoanoa o 50 μm (hōʻike nā hopena hōʻike ma luna nei ʻo 100 μm ka mea maikaʻi loa, no laila ʻo ka mānoanoa o ka paʻi kiʻekiʻe ʻo 50μm = 50μm. μm), a laila e hoʻokomo i ka chip, a laila e hoʻi i ka 80 s. Aneane ʻaʻohe puka i ka solder ma hope o ka paʻi mua ʻana a me ka reflow, a ʻo ka paʻi solder i ka paʻi lua he liʻiliʻi, a he liʻiliʻi ka lua kuʻi, e like me ka hōʻike ʻana ma ke Kiʻi 14.

Ma hope o ʻelua paʻi ʻia ʻana o ka paʻi solder, kiʻi hollow

4.3 Hōʻoia o ka welding cavity hopena

Iecaianoaaiiuo o 2000 huahana (ka mānoanoa o ka paʻi mua kila mesh mea he 75 μm, ka mānoanoa o ka lua paʻi kila mesh mea 50 μm), 'ē aʻe kūlana i hoʻololi 'ole, random ana o 500 QFN a me chip welding ana ana, ua ike i ke kaʻina hana hou ma hope o ka reflux muaʻaʻohe lua, ma hope o ka lua o ka reflux cavity. ʻO ka nui o ka lua o ka chip he 4.1%. Ke hoʻohālikelike ʻia me ke kaʻina hoʻoheheʻe paʻi paʻi hoʻokahi a me ke kaʻina hana i hoʻopaʻa ʻia e DOE, ua hoʻemi nui ʻia ka lua kuʻi, e like me ka hōʻike ʻana ma ke Kiʻi 15. ʻAʻole i loaʻa nā māwae chip ma hope o nā hoʻokolohua hana o nā huahana a pau.

5 Hōʻuluʻulu manaʻo

ʻO ka hoʻonui ʻana i ka nui o ka paʻi paʻi solder a me ka manawa reflux hiki ke hōʻemi i ka wahi o ka lua kuʻi, akā nui ka nui o ka lua. ʻO ka hoʻohana ʻana i ʻelua ʻenehana hoʻoheheʻe reflow paʻi paʻi hiki ke hoʻonui a hoʻonui i ka nui o ka lua. Hiki ke 4.4mm x4.1mm a me 3.0mm x2.3mm ka wiliwili wahi o QFN circuit bare chip i ka hana nui ʻia ʻO ka nui o ka lua o ka reflow welding e hoʻomalu ʻia ma lalo o 5%, e hoʻomaikaʻi ai i ka maikaʻi a me ka hilinaʻi o ka reflow welding. Hāʻawi ka noiʻi ʻana i kēia pepa i kahi ʻōlelo koʻikoʻi no ka hoʻomaikaʻi ʻana i ka pilikia o ka lua kuʻi ʻana o ka ili kuʻi ʻāina nui.

Ka manawa hoʻouna: Jul-05-2023