ʻO ka papa kaapuni PCBA kūlana kiʻekiʻe DIP plug-in selective wave soldering welding design e pono e hahai i nā koi!

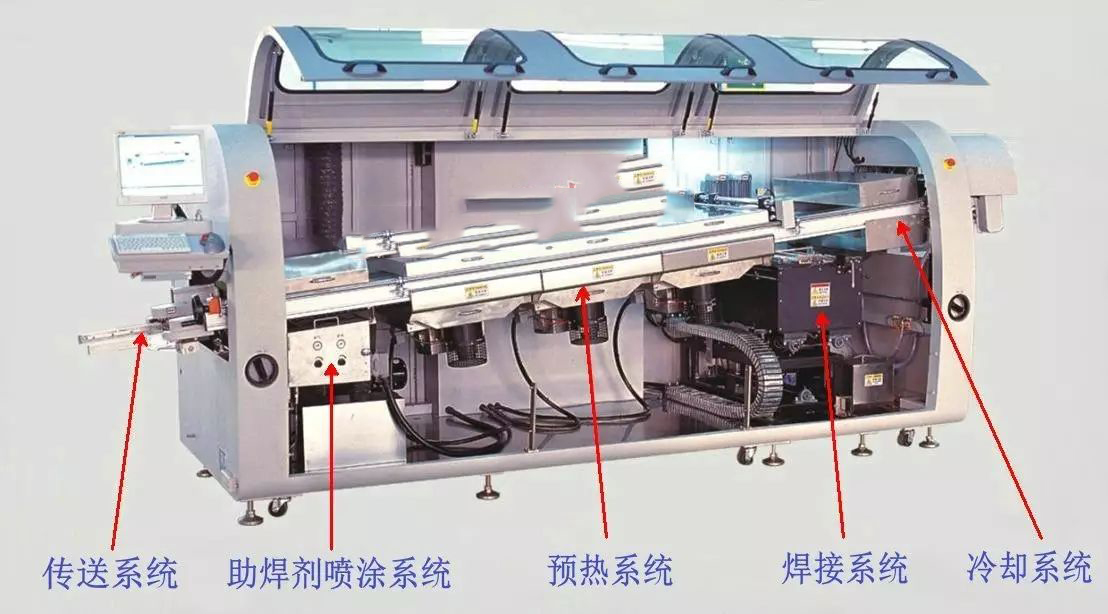

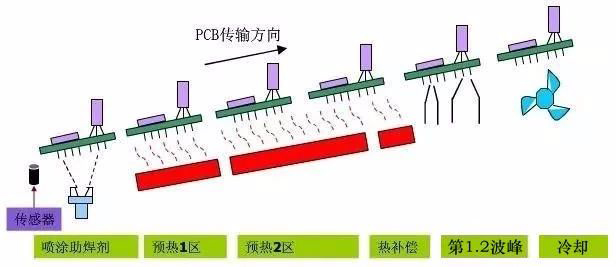

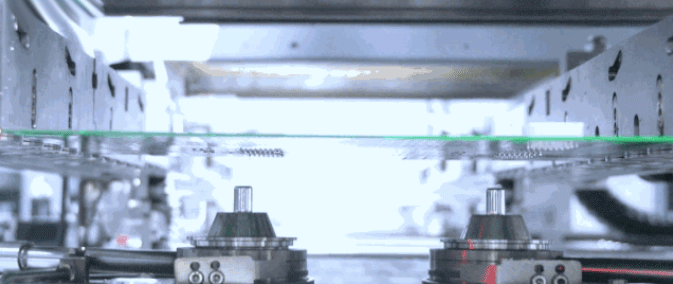

Ma ke kaʻina hana uila uila maʻamau, hoʻohana ʻia ka ʻenehana welding nalu no ka wili ʻana i nā ʻāpana papa i paʻi ʻia me nā mea hoʻokomo perforated (PTH).

He nui nā hemahema o ka hoʻoheheʻe ʻana i ka nalu DIP:

1. ʻAʻole hiki ke hoʻohele ʻia nā mea SMD kiʻekiʻe, maikaʻi-pitch ma luna o ka ʻili kuʻi;

2. He nui nā hoʻopaʻa ʻana a me ka nalowale ʻana;

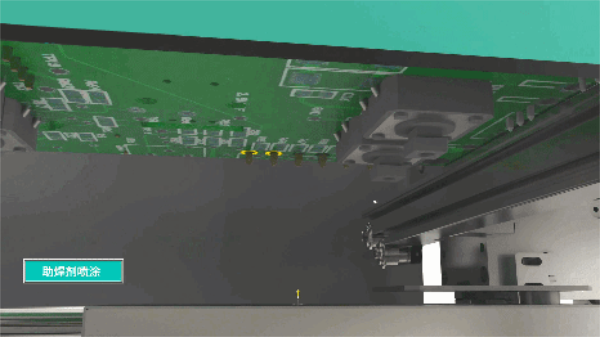

3.Flux pono e pulu; ʻo ka papa i paʻi ʻia ua wili ʻia a hoʻololi ʻia e kahi haʻalulu wela nui.

Ke piʻi aʻe nei ka nui o ka hui kaapuni o kēia manawa, he mea hiki ʻole ke puʻunaue ʻia nā ʻāpana SMD kiʻekiʻe kiʻekiʻe, maikaʻi-pitch ma ka ʻili kūʻai. ʻAʻohe mana o ka hana kuʻuna nalu maʻamau e hana i kēia. ʻO ka maʻamau, hiki ke hoʻokaʻawale ʻia nā ʻāpana SMD ma ka ʻili kūʻai. , a laila hoʻoponopono lima i ke koena plug-in solder ami, akā, aia ka pilikia o ka maikaʻi ʻole o ka hui pū ʻana.

E like me ka paʻakikī o ke kūʻai ʻana i nā ʻāpana ma waena o ka puka (ʻoi aku ka nui o ka mana nui a i ʻole nā mea hoʻonaninani maikaʻi), ʻoi aku ka paʻakikī o nā huahana me ke alakaʻi ʻole a me ka hilinaʻi kiʻekiʻe, ʻaʻole hiki ke kūʻai ʻia ka maikaʻi o ka soldering manual e hui hou i nā lako uila kiʻekiʻe. E like me nā koi o ka hana ʻana, ʻaʻole hiki ke hoʻokō piha ka hoʻoheheʻe nalu i ka hana a me ka hoʻohana ʻana i nā ʻāpana liʻiliʻi a me nā ʻano like ʻole i ka hoʻohana kikoʻī. Ua ulu wikiwiki ka noi o ka nalu koho i nā makahiki i hala iho nei.

No nā papa kaapuni ʻo PCBA me nā ʻāpana perforated THT wale nō, no ka mea, ʻo ka ʻenehana hoʻoheheʻe ʻana i ka nalu ʻo ia ke ʻano hana ʻoi aku ka maikaʻi i kēia manawa, ʻaʻole pono ke hoʻololi i ka soldering nalu me ka soldering koho, he mea nui loa. Eia nō naʻe, he mea nui ka hoʻoheheʻe koho ʻana no nā papa ʻenehana hui ʻia a, ma muli o ke ʻano o ka nozzle i hoʻohana ʻia, hiki ke hana hou ʻia nā ʻenehana hoʻoheheʻe nalu ma ke ʻano nani.

ʻElua kaʻina hana like ʻole no ka hoʻoheheʻe ʻana: kauo ʻana a me ke kūʻai ʻana.

Hana ʻia ke kaʻina hana hoʻoheheʻe kauo koho ma ka nalu solder ʻuʻuku liʻiliʻi. He kūpono ke kaʻina hana wili no ke kūʻai ʻana ma nā wahi paʻa loa ma ka PCB. No ka laʻana: nā hui solder pākahi a i ʻole nā pine, hiki ke kauo a hoʻopaʻa ʻia i kahi lālani o nā pine.

Selective wave soldering technology is a new developed technology in SMT technology, and its appearance largely meet the assembly requirements of high-density and overse mixed boards PCB. Loaʻa nā pōmaikaʻi o ke kūʻai ʻana i ka nalu koho i ka hoʻonohonoho kūʻokoʻa o nā ʻāpana hui solder, ka haʻalulu haʻahaʻa haʻahaʻa i ka PCB, ka liʻiliʻi ʻana o ka flux spraying, a me ka hilinaʻi kūʻai ikaika. Ke lilo mālie nei ia i ʻenehana soldering indispensable no nā PCB paʻakikī.

E like me kā mākou e ʻike ai, ʻo ka PCBA circuit board design stage e hoʻoholo i ka 80% o ke kumukūʻai hana o ka huahana. Pēlā nō, paʻa nā hiʻohiʻona maikaʻi i ka manawa hoʻolālā. No laila, he mea nui e noʻonoʻo pono i nā mea hana i ka PCB kaʻapuni papa hana hoʻolālā.

He ala koʻikoʻi ka DFM maikaʻi no ka PCBA e kau ana i nā mea hana e hōʻemi i nā hemahema o ka hana ʻana, hoʻomaʻamaʻa i ke kaʻina hana, hoʻopōkole i ka pōʻai hana, hoʻemi i nā kumukūʻai hana, hoʻomaikaʻi i ka mana maikaʻi, hoʻomaikaʻi i ka mākeke huahana, a hoʻomaikaʻi i ka hilinaʻi huahana a me ka lōʻihi. Hiki iā ia ke hiki i nā ʻoihana ke loaʻa nā pōmaikaʻi maikaʻi loa me ka liʻiliʻi o ka hoʻopukapuka kālā a loaʻa ʻelua i ka hopena me ka hapalua o ka hoʻoikaika.

ʻO ka hoʻomohala ʻana i nā ʻāpana mauna o luna a hiki i kēia lā, pono i nā mea ʻenekinia SMT ʻaʻole i mākaukau i ka ʻenehana hoʻolālā papa kaapuni, akā no ka loaʻa ʻana o ka ʻike hohonu a me ka ʻike waiwai i ka ʻenehana SMT. No ka mea, ʻo ka mea hoʻolālā i maopopo ʻole i nā ʻano kahe o ka solder paste a me ka solder he paʻakikī ke hoʻomaopopo i nā kumu a me nā loina o ka bridging, tipping, tombstone, wicking, etc. He mea paʻakikī ke hoʻoponopono i nā pilikia hoʻolālā like ʻole mai nā hiʻohiʻona o ka hana hana hoʻolālā, ka hoʻāʻo ʻana, a me ka hōʻemi ʻana i ke kumukūʻai a me ka uku. ʻO kahi hoʻonā i hoʻolālā maikaʻi ʻia e kūʻai i ka nui o ka hana ʻana a me ka hoʻāʻo ʻana inā ʻilihune ka DFM a me DFT (design for detectability).